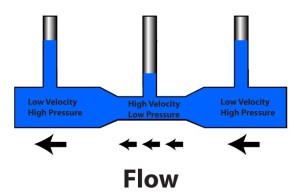

The automotive industry has taken B’s theorem of hydrodynamics such that for an inviscid flow of a nonconducting fluid (in our case, air), an increase in the speed (velocity) of the fluid occurs simultaneously with a decrease in pressure.

Extrapolated, for a given flow area and corresponding air flow velocity, if the flow area is reduced, the air velocity increases. If there were a liquid chamber connected both up and downstream of the change in area, conceivably said fluid could be drawn up into the flowing air and form a mixture differential pressure across a newly invented throttle plate.

With that simple definition, the earliest carburetors came into being. Very crude devices but they were adequate for the also very crude engines. They didn’t rev very high, didn’t make much power, and leaded fuel was very forgiving to tuning, runability and the like.

With that simple definition, the earliest carburetors came into being. Very crude devices but they were adequate for the also very crude engines. They didn’t rev very high, didn’t make much power, and leaded fuel was very forgiving to tuning, runability and the like.

With today’s highly refined, highly tuned, high revving engines and pollution requirements, as they are, a sophisticated carburetor is needed. They have many metering circuits, accelerator pumps, air cutoff valves, idle air mixture screws, low-mid-high adjustability, and they still are only adequate…all to meet pollution requirements.

Over a lifetime of working with carburetors, I have figured out how to make them perform well; I’m good at it.

Lately, I’ve become weary of their quirks and am seriously looking at a lower cost alternative. Enter electronic fuel injection (EFI).

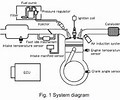

EFI is not new, the car people have been using and refining their mass- produced systems since the late 1970’s. Hilborn and Kinsler made mechanical fuel injection in the late 1950’s for their race cars. Those systems still work …with some limits…but the idea is sound. Add some critical electrical electronic sensors (such as an Oxygen or “lambda” sensor) and a direct measurement of the burned fuel quality feeds directly into a box that adjusts the length of time a fuel valve, or injector (under constant pressure), and is open or closed to allow or stop fuel flow into the engine. The electronics control via PWM or Pulse Width Modulation is from a lookup table based on sensor input to maintain an ideal stoichiometric mixture. Your car has this same lookup table. Your motorcycle too. And stioch mixture is related to gasoline and its optimal air/fuel, excuse me, stoichiometric, mixture to properly ignite and burn inside the engine.

It’s very precise control.

My goal is to have a completely new EFI system for the cost of a carburetor rebuild.

Stay tuned (all puns intended) to see if I can make this work!

Stay tuned (all puns intended) to see if I can make this work!